Happy Together: Digital and Screen Printing

How to make digital and screen printing coexist in your apparel decoration shop

Over the last several years, we’ve seen digital decorating come into its own in the apparel decorating community. While the early days of direct-to-garment (DTG) saw rough waters and big challenges, the technology has become a large presence in many shops across the country. And with the evolution of e-commerce, print-on-demand (POD), and the massive increase in popularity of custom designs, digital decorating has grown exponentially.

The advent of direct-to-film (DTF) printing has also pushed digital decorating further into the limelight. While still mainly a transfer process, DTF has put the spotlight on digital printing now more than ever, with many apparel decorators looking to incorporate these processes into their current technology lineup.

But for those that are accustomed to the process and technique of screen printing, it isn’t necessarily a simple process to integrate digital into your shop. In fact, it isn’t always the right decision. If you want to find a way to have screen printing and digital decorating coexist in your shop, there are a few things you need to consider from both a process and production viewpoint as well as a business perspective.

Don’t Fear Digital Printing

Let’s first set the record straight: screen printing will always have a place in apparel decorating. It’s not “dying” or going away. However, to not acknowledge the importance of digital printing would be sticking your head in the sand. The impact it’s had on the industry is undeniable.

“I think over the past 10 years there has been a huge shift when it comes to the viability of digital printing inside of an apparel decoration business,” says Kevin Oakley, co-founder and chief revenue officer at Stoked on Printing. “Digital printing has really forced screen printing companies to look at different ways that [it] can be a tool in their business.”

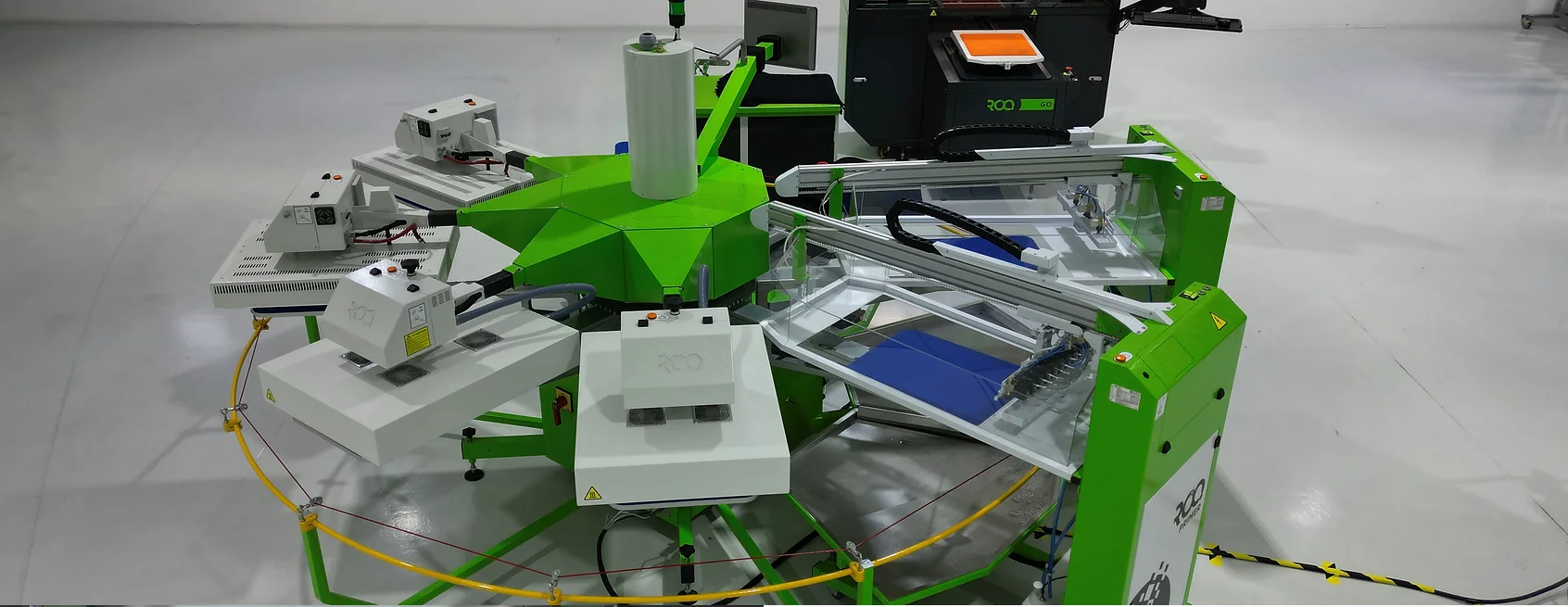

Ross Hunter, president of ROQ.US, really saw DTG take off during the COVID-19 pandemic. “It took people’s buying habits changing,” he notes. “When it moved from buying at the mall to ‘order what I need on the internet,’ digital printing took off like wildfire. With that, digital had to grow up quickly.”

That rapid change has had a bittersweet reception in the industry by some accounts. But rather than treat digital printing as a “replacement” for screen printing, or as something to fear, Hunter encourages shops to treat it as a potential tool within their business model.

“[Digital] eliminates a lot of time and labor,” he explains. “From that perspective, it’s truly an enhancement to screen.” He notes that digital printing right now from a chemistry standpoint (i.e., the higher cost of digital inks) is just one reason why it serves as a tool, not a replacement.

Plus, nothing comes close to matching screen when it comes to bulk printing. “When looking at where digital stands inside of a shop, you still have a big advantage toward screen printing when you have longer runs,” says Oakley. Where digital does supplement screen is smaller, custom work. “Once you start to get to smaller quantities, it just doesn’t make sense to go through the process of artwork separating/screen making/setting up the press. There is also a huge advantage of being able to print unlimited colors within the design when it comes to the sales side.”

How to Evaluate Adding New Technologies

All that to emphasize that digital and screen can coexist within the apparel industry. However, it comes down to the right business model, meaning if you’re a screen-print-only shop, there are a lot of things to consider before purchasing digital equipment. In the long run, it might not make sense for your business.

“The first thing I would look at is who are my customers and why would adding these processes into my shop add value to them,” Oakley advises. “During the exploring process, you need to look at the different types of digital printing (DTF, DTG, hybrid) to really see where it can benefit as well as makes the most sense from a cost perspective.”

Hunter explains that, just because you go to a trade show and see the shiny new toy, doesn’t mean you should buy it. You need to know all the things it encompasses, such as:

- Will your customers like the hand and image it puts out as compared to screen?

- Do you have the market for it (i.e., lower quantity runs)?

- Do you understand the equipment and how to run it?

- Do you have time to maintenance it?

- Do you have the physical space for it?

- What additional software is needed?

- What is the cost per impression going to be and is there a way to make your desired profit?

Breaking these questions down, Hunter draws attention to two big considerations: cost and physical layout. “It’s the equivalent of buying a G6 Learjet,” he says. “There are different pricing models for both technologies. If you’re trying to sell 10K shirts and you’re running them digitally, can that bear your pricing model? You’re going to have a tough time getting large-quantity runs and still making money.”

Don’t forget about the cost of maintenance, either. “[Digital] requires daily maintenance,” Hunter elaborates. “Things that will clog, things that will break, software that won’t work.”

On top of that, the physical layout of your shop must also be considered. When you put two technologies like screen and digital in the same facility, they have different physical requirements, such as humidity, heat, venting, etc., Hunter says. “The biggest mistake people make is throwing them in the same space as each other,” he adds. “The glues, the fabric dust, the heat from your dryers, all of these are very bad for digital. Make sure from a planning standpoint that you consider the physical space. If you don’t, what’s the cost to build it.”

Looking at the topic from a different lens, there are shops out there that offer digital only and are considering making the leap to screen. There’s some homework involved there, too. “It is true that it’s more expensive to get started in screen printing and [to] run more efficient, but once you do, you will be able to produce products cheaper and, depending on the product, at a better quality,” says Oakley.

Digital and Screen: A ‘Perfect’ Match

Once you’ve determined that it makes sense to have both screen and digital capabilities in-house, it’s time to make the two peacefully coexist. On top of keeping them in separate spaces, there are some other ways to run both efficiently.

“We keep these departments separate, with different teams operating [each] as we focus a lot of our digital printing with print-on-demand, which is a completely different workflow than bulk screen printing,” explains Oakley of the setup at Stoked on Printing.

Hunter strongly supports keeping the two separate. “Treat them as two separate businesses,” he advises. “Those models have different costs. … There are two different clienteles. The folks that need and want each are much different from each other. If you’re doing small-run printing, those clients care about something different than the client buying bulk is going to care about.”

Oakley also notes that while some cross training between screen and digital is good, there can be a few challenges there. “You most certainly can take team members that are trained in screen printing and get them up and going in digital pretty quickly. However, the opposite is not the case as screen printing is a very skilled position versus digital, [which] has a lot more automation,” he says.

For this reason, among others, Hunter feels shops should keep two separate teams at the operator level. “I’m a big fan of dedicated employees,” he says. “Cross training is great for certain positions, especially at a high level like a production manager. They need to be trained in both. But at the operator level, it’s important to keep them separate. You need those production people to be amazing at each — it’s a different skill level.”

Oakley adds one more thought when it comes to operating screen a digital under the same roof: Make sure the process is controlled at the sales level. “Through the sales process, you can train the staff to locate opportunities to push a project one way or the other based on costing or product selection,” he says.

At the end of the day, digital and screen both play a vital role within the apparel decorating industry. Whether or not both have a place under your roof must be determined through research and business evaluation. “Anyone looking at adopting new technology, do your homework, talk to other people who do it, other people who do more than one thing, make a business plan, and then invest,” Hunter finishes.